Coarse-Grained Atomistics

Various computational techniques have been established that describe and predict the mechanics and physics of materials on many different length and time scales, from atomistic methods such as molecular statics and dynamics all the way up to the largest length scale where continuum mechanics and the finite element method are powerful modeling tools. Each method is appropriate for a particular, limited range of length and time scales. Unfortunately, many problems fall into a gap between length scales, where none of the aforementioned methods is applicable alone. Therefore, we develop tools that bridge across scales from individual atoms to the significantly larger continuum scales, by merging techniques of molecular statics and dynamics with those engineering methods at the continuum scale. The ultimate goal is a computational toolbox that enables us to understand the basic microstructural mechanisms in crystalline solids, including defect interactions, material failure, heat and mass transfer, to name but a few. The focus of our research lies equally on the development of efficient modeling tools and on the application of such tools to study the multi-physics behavior of crystalline solids.

The quasicontinuum (QC) method is a coarse-graining technique aimed at modeling multiscale phenomena in crystalline materials. While the original method focused on zero-temperature mechanics, recent advances have enabled its extension to study e.g. thermo-mechanical coupling, heat conduction, and mass diffusion. State-of-the-art QC techniques achieve spatial coarse-graining effectively by tracking only a small subset of all atoms in a system (the so-called representative atoms). Such techniques thus facilitate the computational modeling of system sizes previously unattainable via classic molecular statics and dynamics. While spatial coarse-graining has been addressed by many, effective temporal coarse-graining has remained the “holy-grail” of QC modeling, with most existing techniques requiring a-priori knowledge about where full atomistic and coarse-grained domains are needed, hence not being adaptive and seamless. In addition, mass and heat transport are complex challenges that call for the merging of techniques form, among others, solid mechanics, physics, and statistical mechanics.

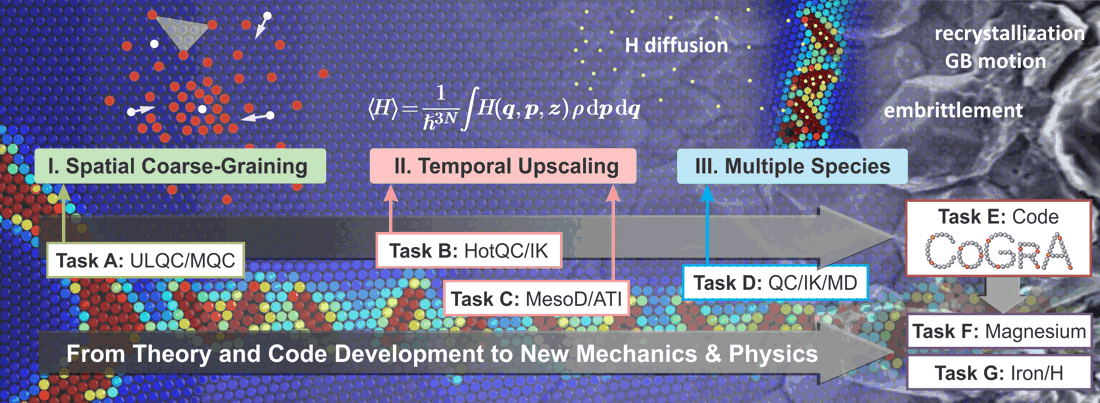

Through this project, we aim to develop seamless simultaneous temporal and spatial coarse-graining techniques, which can account for statistical thermal vibrations of molecules and emergent effects on observable phenomena across scales, such as thermo-mechanical wave propagation, heat and mass transport, etc. Seamless temporal coarse-graining is motivated by an adaptive refinement and coarsening QC methodology, the spatial version of which was shown to be extremely efficient in modeling large-scale crystal deformation simulations; see our work in external page JMPS (2015). Using new adaptive spatio-temporal coarse graining techniques, we aim for a holistic and modular simulation environment to bridge across length and time scales. We will apply the new techniques to the specific problems of recrystallization in magnesium during thermo-mechanical processing and corrosion in iron by hydrogen embrittlement, both of which are well-known phenomena that, unfortunately, cannot be simulated by either atomic-scale nor continuum-scale models alone.

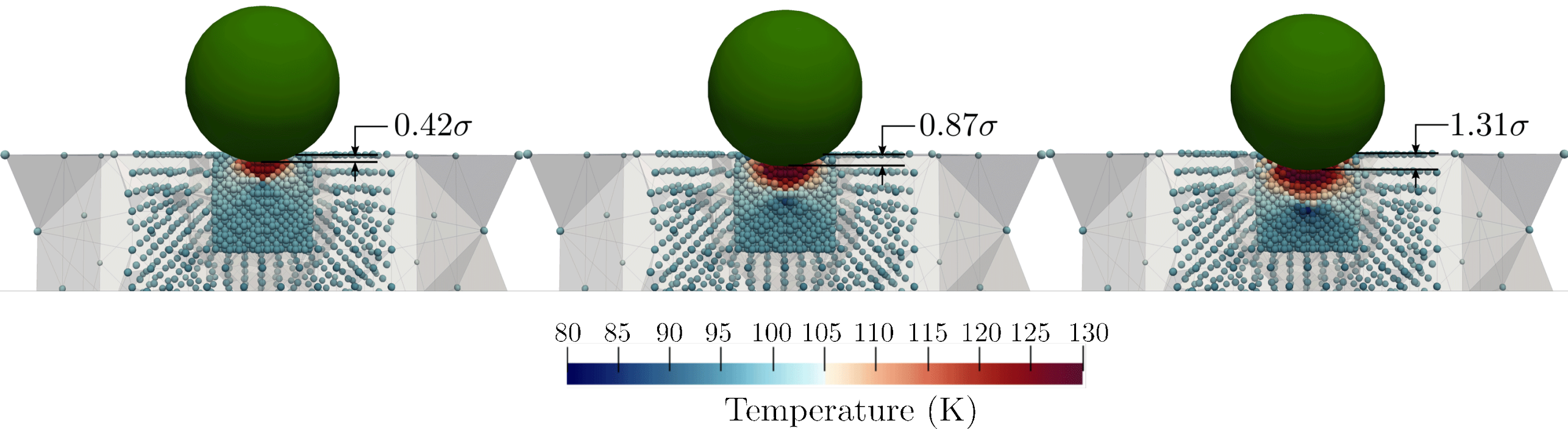

We have developed a framework to model seamless adiabatic temperature variations and thermo-mechanical coupling. Below, we show an example of an 8000nm3 copper single-crystal subjected to a nano-indenter of radius 3nm, with quiescent conditions at 100 K. As the indenter is lowered, the local temperature increases due to thermo-mechanical coupling. In dynamic simulations, such thermo-mechanical coupling emerges as thermo-mechanical wave propagation, capturing the local heating due to linear and nonlinear acoustic waves.

Much of our prior work focused on seamless spatial coarse-graining without requiring a-priori knowledge about where full atomistic resolution would be needed during the course of a simulation. This is achieved by a nonlocal QC formulation that adaptively changes its discretization based on a local criterion to trigger mesh refinement. Our nonlocal formulation, among others, avoids force artifacts at the atomistic-continuum interface (see below). While our prior work was based on a total-Lagrangian finite element interpolation in the continuum region, ongoing research investigates an updated-Lagrangian setting as well as meshless interpolation schemes.

Scale-bridging techniques like QC are ideal when full atomistic resolution can be restricted to small regions of interest. Such a scenario is given when investigating, e.g., the mechanics and physics of grain boundaries in metals. Here, full resolution is restricted to the grain boundary while efficiently coarse-graining the crystal away from the grain boundary. Shown below is an example of a QC-coarsened simulation domain with a grain boundary.

To visualize the adaptive remeshing strategy, the below movie illustrates the set of all sampling atoms (selected atoms where the total energy and all derived quantities are computed, akin to quadrature points in the finite element method). Shown is the outcome of a nanoindentation simulation at zero temperature in pure copper, which leads to the creation and motion of dislocations through the crystal with increasing indenter load. The color code indicates the level of centrosymmetry (blue implying perfect centrosymmetry, yellow implying high local disorder), so that dislocation cores appear in red. The left pane shows the total simulation domain, while the right pane shows only the top central portion of simulation domain on the left. All sampling atoms are shown with full resolution emerging underneath the indenter as well as around the moving dislocations, while the remaining sample (especially far from the indentation site) is efficiently coarse-grained.

This research is sponsored by the European Research Council (ERC) through the Consolidator Grant COGRA.

Publications

Atoms are small and fast, devices are large and slow: COGRA bridges the gap

The Project Repository Journal (PRJ), Volume 12 (Jan 2022). external page Link to the overview article describing the COGRA project.