Biomimetic Spinodoids

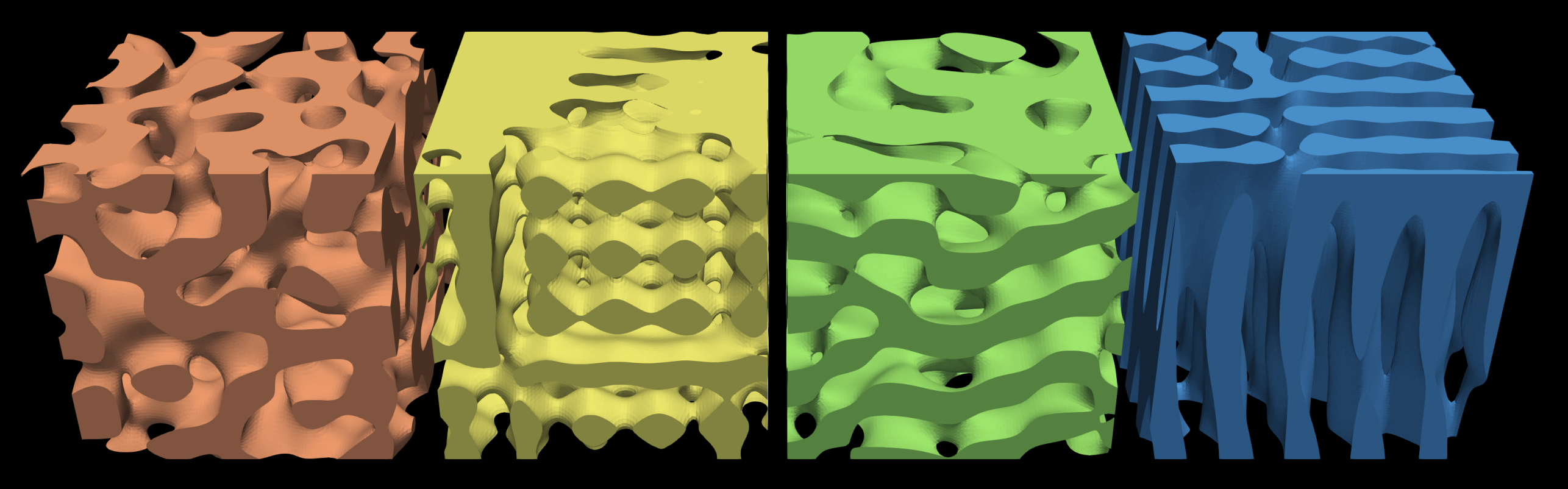

After a decade of periodic truss-, plate-, and shell-based architectures having dominated the design of metamaterials, we introduced the new class of spinodal topologies. Inspired by natural self-assembly processes, spinodal metamaterials are based on the microstructures observed during spinodal phase separation in, e.g., nanoporous metal foams, microemulsions, and polymer blends. These metamaterials can be fabricated either by additive manufacturing of topologies extracted from external page spinodal decomposition simulations (or a close approximation of the solutions, in which case we speak of external page spinodoid) or via external page self-assembly in polymeric emulsions. In contrast to existing metamaterial design spaces, spinodal metamaterials offer a large and seamless design space in terms of tunable (direction-dependent) topological and mechanical properties as well as excellent mechanical properties such as extremely high resilience and optimal scaling of stiffness with density.

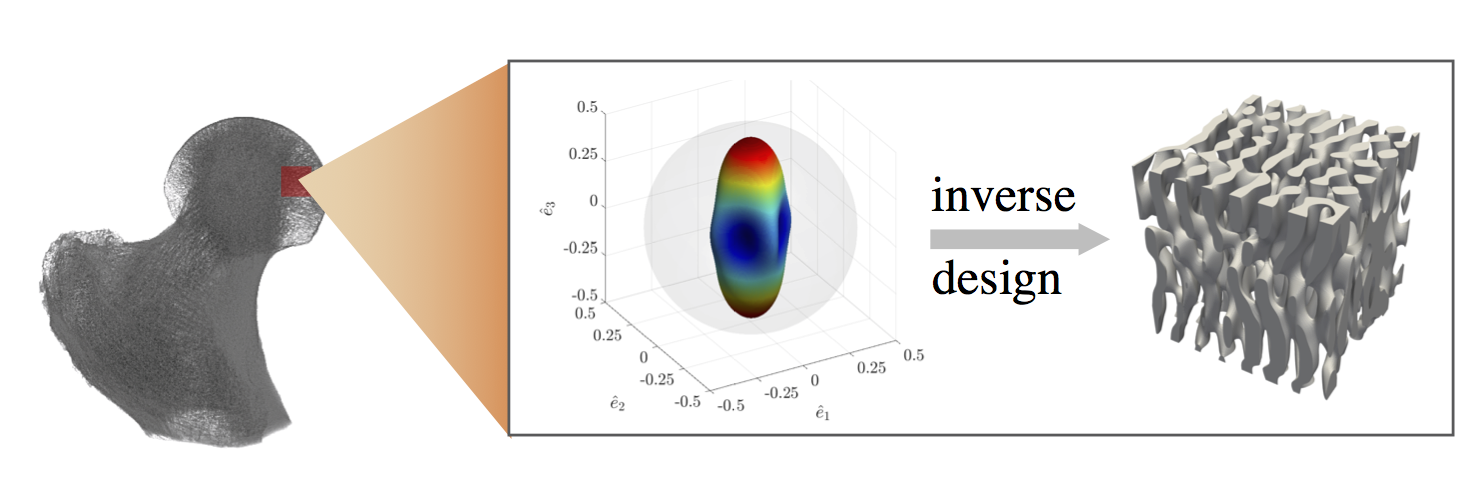

We recently introduced an efficient and robust machine learning (ML) technique for the external page inverse design of (meta-)materials which, when applied to spinodoid topologies, enables us to generate uniform and functionally graded cellular mechanical metamaterials with tailored direction-dependent (anisotropic) stiffness and density. We specifically predicted biomimetic artificial bone architectures (based on spinodal topologies) that not only reproduce the properties of trabecular bone accurately but also even geometrically resemble natural bone. In on-going work with our collaborators, we are investigating the possibility of inverse-designed synthetic bone implants. Overall, our ML-driven approach for creating forward and inverse maps of the structure–property relation accelerates the design process of metamaterials with a wide range of tunable mechanical response (anisotropic stiffness only being the tip of the iceberg).

Spinodal metamaterials cover a large and seamless range of anisotropic (direction-dependent) topological and mechanical properties, as demonstrated, e.g., by their tailorable anisotropic elastic moduli – creating materials that are stiff in some directions and soft in others. Spinodal topologies consist of smooth, non-intersecting, and bi-continuous surfaces that avoid points of stress concentration (in contrast to truss- and plate-based metamaterials) while also showing excellent scaling of stiffness and strength with respect to density (leveraging the benefits of doubly-curved surfaces that engage slender structures primarily in stretching rather than bending). The non-periodicity and lack of symmetry in spinodal topologies make them more resilient to fabrication-based symmetry-breaking defects – by contrast to periodic metamaterials whose sensitivity to defects deteriorates their mechanical properties. The non-periodicity also offers unprecedented opportunities for spatially-variant architectures for functional grading without issues arising from unit cell tessellation and discontinuous topologies (which, in contrast, is an active challenge for periodic topologies including trusses, plates, and shells).

ML-driven Inverse design

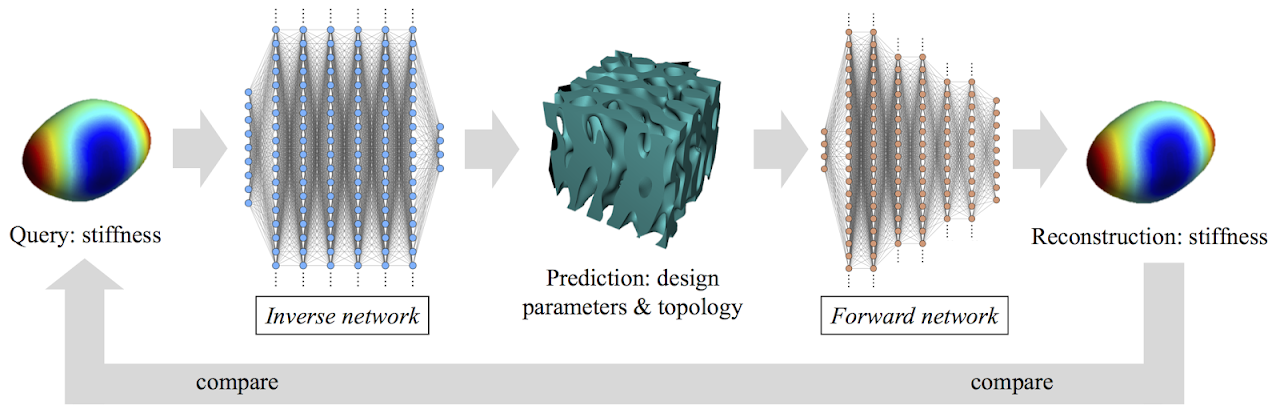

Structure-property relations of all existing materials, including spinodal metamaterials, have primarily been explored in a forward fashion: given a microstructure, one extracts the effective properties by methods of homogenization. The inverse challenge – identifying a microstructural topology that meets the mechanical property requirements – has often been addressed by inefficient trial and error. In addition, while the forward problem, i.e., mapping from topological parameters to property space, is well-defined, the inverse problem is ill-posed (multiple topologies can have the same or similar effective properties). To this end, we introduced a novel data-driven approach based on the integration of two neural networks for the forward- and inverse-problems that renders the inverse design challenge well-posed. This approach, in contrast to topology optimization methods, provides a computationally inexpensive two-way relationship between design parameters and mechanical properties.

Synthetic bones or bone-mimetic scaffolds and implants are prime examples that can benefit from systematic inverse design. Matching the highly anisotropic and heterogeneous topological and mechanical properties of bones in 3D-printed architectures (important for successful long-term compatibility) has remained a challenge. Our ML approach bypasses this challenge and applies an inverse model trained on spinodoid metamaterials to the in-silico generation of artificial trabecular bone. The inverse model accurately predicts topologies that match the target relative density and anisotropic elastic stiffness as well as bear resemblance to the natural bone topologies, and achieves this, remarkably, without prior information about bone during the learning stage.

Code

The numerical code to generate spinodoid topologies is available in the external page GIBBON library.